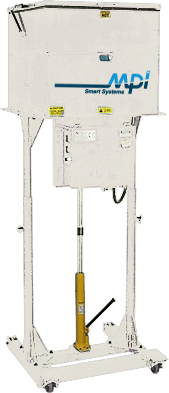

MPI’s new soluble wax-melter is unique to the industry. It is the first melter specifically designed to melt and deliver soluble wax into a reservoir. Because of the unique properties of soluble wax, until now, there has not been an efficient way to prepare soluble wax in a traditional melter.

MPI has devised a way to melt and deliver soluble wax into the reservoir using a precision melting methodology. On-injector melting of soluble wax has been a challenge for the industry for many years. MPI listened and has developed an effective

affordable solution.