The MPI 56 is engineered specifically for operation with thick viscosity, abrasive mixtures used to produce ceramic cores, ceramic parts, and MIM (metal injection molding) patterns. The MPI 56 features easy maintenance and fast material changeover. Precise temperature control prevents binder separation and a unique injection valve system reduces wear. The MPI 56 is designed to meet all your thermoplastic binder, abrasive material injection needs. The MPI 56 is available with clamping force of 25, 38, 50, or 100 tons. An impressive list of standard features and a wide range of options are available. Our engineering support staff is prepared to help determine the configuration that will meet your needs and optimize your throughput.

MPI 56 Series C-Frame

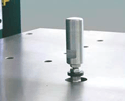

- Injection Valve Assembly

The proprietary design of a sliding spool transfer valve reduces wear of the injection piston and injection valve. Less wear means more throughput and less downtime. - Ceramic Reservoir

Easy removal of the mixer motor assembly for reservoir clean out and mix changeover.

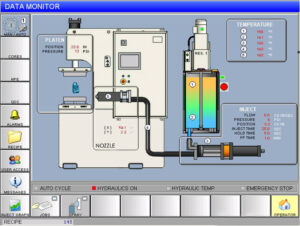

Smart Controls™ with Process Control

Real time graphical representation of pattern cycles compare wax flow and pressure data to predetermined baselines.

Adjustments are intelligently introduced if needed. This significantly reduces set up time.

Tee Slots (optional)

Three parallel tee slots per platen, running perpendicular to the nozzle, provide full coverage die clamping and eliminate stripped threads.

Jib Crane (optional)

The unique combination of Jib Crane and Hydraulic Shuttle Table allow quick, safe pattern removal and die changeovers by a single operator.

Hydraulic Pattern Ejection (optional)

Controlled pattern removal from the lower stationary platen.

Second Shuttle (optional)

Increase machine utilization by injecting one die while performing die disassembly and pattern removal on a second die.

The MPI 56 features:

- Injection capacity: 10.6, 200, 323 cu in (.17, 3.2, 5.3 liter)

- Horizontal parting line injection

- 2-Axis nozzle positioner

- Ceramic reservoir

- Smart Controls™

- Easy Maintenance

- 3 Injection Modes

- Accurate 6-zone ceramic temperature control

- Sliding spool transfer valve

- Hardened injection components

- CE conformity