MPI wax systems will optimize the control of your wax process from melting to pattern injection. Consistent wax patterns can only be achieved if there is a consistent supply of conditioned wax with a viscosity that is appropriate for the pattern. MPI believes that separating wax melting from wax conditioning is essential to maximizing control. That’s why MPI wax melters control two important variables – the wax melt temperature and the wax melt rate. MPI’s Wax Level Control accomplishes this by automatically and continuously replenishing the wax conditioning reservoir with small amounts of source wax. The MPI 5-zone Temperature Control System monitors wax temperature at specific locations, providing the most accurate temperature control with the highest throughput in the industry. By maintaining a set temperature through all zones, we are able to achieve extraordinary pattern-to-pattern repeatability.

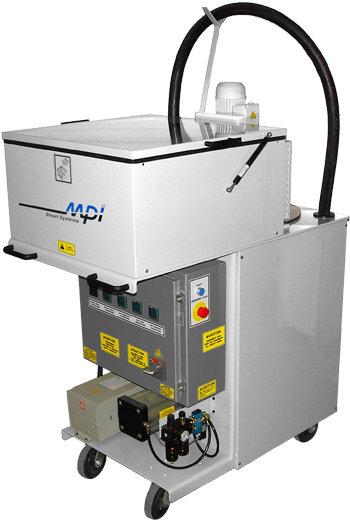

MPI 95-25

The Model 95-25 Series Wax melting and condition unit is designed for transferring liquid wax to injection machines. It can be supplied as a portable unit for manual filling the injectors or as a stationary unit with rigid transfer lines for automatically feeding up to 4 injection machines.

- Available as portable or stationary unit

- Available with 50 or 200 lb/hr melt capacity

- Unit has tightest temperature control in the industry. Supplies uniform conditioned wax to each injection machine

- Large hopper capacity, expandable

- Low level alarm

- Melts all type waxes, slab, flake, or pellet wax

- Available vacuum load feed

Eliminate the leading cause of problems in the wax room, UNEVEN WAX TEMPERATURE!

A constant temperature into your wax injector yields patterns with dimensional accuracy. Remember – wax temperature variation is the leading cause of pattern defects!

Standard Models:

95-25-50 (50 lb/hr melting)

95-25-200 (200 lb/hr melting)