MPI offers the most sophisticated wax injection systems in the industry, generating higher casting yields, more patterns per hour and increased productivity and throughput. Our Smart Process Control provides real time monitoring and control of all injection parameters and feature an intuitive Windows based touch screen. Our wax conditioning technology maintains a constant wax viscosity which produces consistent wax patterns and our quick change technology allows you to change dies in just 60 seconds – minimizing transition times and maximizing throughput. All MPI systems come with our world class technical support and training.

MPI 55 IGT Industrial Gas Turbine

The Model 55 IGT Series wax injector is a C-Frame hydraulic press designed specifically for Industrial Gas Turbine products. The machine is available in 50 and 100 ton clamping forces. The C-Frame clamping unit is the most ergonomic for the operator, providing unobstructed access to their work area. The unique frame design allows the operator to remove large patterns without having to climb onto the machine.

- Rigid C-Frame- Parallel Die Opening, uniform die clamping, easy die access.

- Smart Controls™- Process control, with real time injection graphing.

- Injection System- Tightest temperature control in the industry.

- Inject your wax into your dies at MPI and decide for yourself.

Removable Wax Reservoir and Docking Station

MPI’s new removable wax reservoir and docking station was designed for wax rooms with more than two waxes and will instantly reduce downtime while dramatically improving productivity.

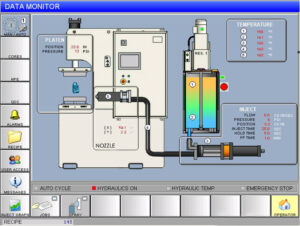

Smart Controls™ with Process Control

Real time graphical representation of pattern cycles compare wax flow and pressure data to predetermined baselines.

Adjustments are intelligently introduced if needed. This significantly reduces set up time.

Tee Slots (optional)

Three parallel tee slots per platen, running perpendicular to the nozzle, provide full coverage die clamping and eliminate stripped threads.

Jib Crane (optional)

The unique combination of Jib Crane and Hydraulic Shuttle Table allow quick, safe pattern removal and die changeovers by a single operator.

Hydraulic Pattern Ejection (optional)

Controlled pattern removal from the lower stationary platen

3 Axis Nozzle Positioner (optional)

Motor driven x-y-z nozzle positioning allows for nozzle alignment with any die design.

Standard Models:

| 55-50-IGT | 50 ton (45 Tonnes) | C-Frame with 40″ (1016mm) daylight |

| 55-100-IGT | 100 ton ( 90.7 Tonnes) | C-Frame with 50″ (1270mm) daylight |