The Model 20-14 pictured above is one example of our intuitive Automated Pattern Assembly Systems (APAS). Like all our APAS systems, it incorporates significant technological advancements as well as over twelve years of customer feedback. All of our APAS systems give you the flexibility to perform high-quality, precision robotic assemblies from the simplest commercial jobs to the most complex multipiece, multi-level wax assemblies required by the medical and aerospace industries, including single crystal turbine blades.

Automated Pattern Assembly Systems (APAS)

Think Inside the Box!

The Revolutionary Automated Pattern Assembly Systems (APAS).

- Built around MPI’s patented 100% fusion welding process.

- Versatile 6-axis robots can easily handle complex multi-level, multi-part assemblies.

- Large pattern loading station.

- Large, robust runner station ergonomically designed for easy loading and unloading.

- Intuitive Smart Controls™ to ensure consistent results with virtually no supervision.

- Robot programming knowledge not required to run the cell – operator can be trained in one day.

- Automated robot end-of-arm tool change allows for job changeover in less than a minute.

- Automatic Tool ID System allows wax assembly “recipes” to be automatically entered into the system to ensure that the proper robotic tools, wax runner, and wax patterns are loaded for the job.

- Standalone system that can be integrated into a fully automated wax room.

Automate Your Way to Increased Profitability

Automation has proven time and again that a robotics-based machine outperforms manually created assemblies in accuracy, repeatability, and efficiency.

Our automation partners experience:

- Increased casting yields by up to 30%

- Perfect assemblies 100% of the time

- Cycle times 2–5x faster

- Reduced scrap by an average of 50%

- Fragile assemblies are no problem.

- Round-the-clock productivity

- Relentless quality and consistency

- Increased parts per assembly, improving part/runner yield ratio

Come to MPI and experience Automation and learn more about your ROI opportunities in our Tech Center.

The team at MPI would love to have you come visit our facility in New York, tour our plant, see automated wax injection and automated pattern assembly in person, and begin the process of looking at how we can apply these best practices to your wax room. Learn how repeatable pattern injection and pattern assembly can dramatically impact your scrap rates, throughput and casting yields, all of which shows up in your bottom line. Call today for details and to schedule a trip!

Total Control at Your Fingertips

All automated pattern assembly systems are equipped with MPI’s intuitive Smart System Process Controls, which allow you to monitor all aspects of the system during operation. The controls are also the access point to all other critical data and machine functions.

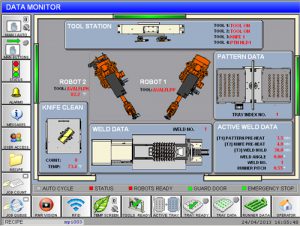

Main Operator Interface Terminal (OIT)

The work area in the center of the Data Monitor window includes interactive OIT touch screen buttons that allow you to instantly monitor the process without ever having to access the Robot Teach pendant:

- Robot status

- Tool station status

- Knife cleaning data

- Weld data

- Active weld data

- Pattern data

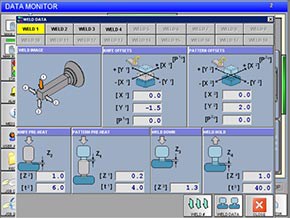

Weld Data Window

The simple intuitive controls enable an average operator to optimize weld parameters. Screen data provides all the variables for optimizing the welding parameters for all welds independently. Screen data includes:

- Runner type graphic updates to match the runner selected

- Weld position graphic displays the current position on the runner that is to be welded next

- Independent presets for all welds

- Weld data for optimizing the weld without the use of the robot teach pendant

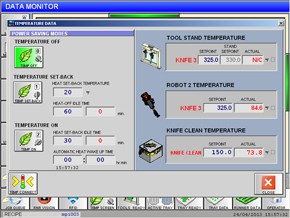

Temperature Data

Accurate PID temperature control that results in precision repeatable welds.

Tools stand temperature control preheat station that eliminates hot knife preheat time from part-to-part changeovers.

- Temperature set back

- Tools stand temperature

- Robot temperature

- Knife clean temperature

- Energy saving mode

Standard Equipment:

- Intuitive Smart Controls™

– 12″ color operator interface terminal (Windows environment) - Automatic tool loading station with hot knife preheat

- 2-Position pattern loading station (rotary table) for easy pattern loading

- Runner loading station that accepts any type of wax assembly

– 2-Sided runner

– Round runner

– Single-plane runner

– and more… - Ergonomic runner loading

- Quick change tooling

- Gripper and vacuum pattern pickup circuits

- Automatic tool identification system (bar code scanning of tooling to verify machine has been setup correctly)

- Network ready

Optional Equipment:

- Tool storage cabinet

- Automatic recipe loading from bar code scan of job traveler

- Automatic runner ID vision system

- Vertical runner station with rotation