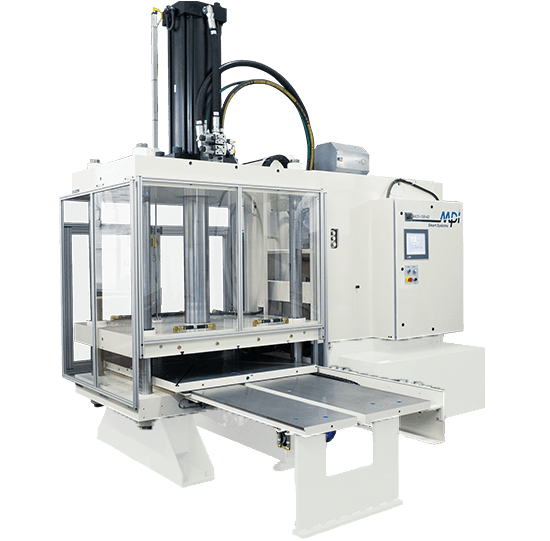

4 Post Wax Injector

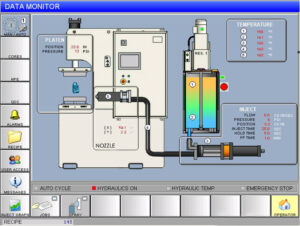

MPI offers the most sophisticated wax injection systems in the industry, generating higher casting yields, more patterns per hour and increased productivity and throughput. Our Smart Process Control provides real time monitoring and control of all injection parameters and feature an intuitive Windows based touch screen. Our wax conditioning technology maintains a constant wax viscosity which produces consistent wax patterns and our quick change technology allows you to change dies in just 60 seconds – minimizing transition times and maximizing throughput. All MPI systems come with our world class technical support and training.