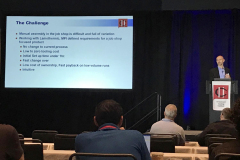

MPI Continues to Demonstrate Its Commitment to Constant Improvement at 2023 ICI Technical Conference & Expo

POUGHKEEPSIE, NY: MPI, the worldwide leader in wax-pattern and ceramic-core injection, assembly, and automation equipment, once again impressed at this year’s ICI Technical Conference & Exposition in Pittsburgh, Pennsylvania. MPI maintains their position at the forefront of innovation as they continue to introduce new products and services.

Those at the well-attended show were introduced to the sticky wax version of the MPI 20-14 Automated Pattern Assembly System (APAS). This new unit, Model 20-12, was designed for commercial foundries where there is low volume, high part diversity and those with high changeover demands. The machine is designed for single-piece flow, offers flexible low-cost tooling, and new parts can be introduced quickly and easily without requiring a robot programmer. The unit has a smaller profile and footprint and is priced to meet the budget sensitive requirements of the commercial industry. A large-screen video helped bring the capabilities of the 20-12 to life at the show.

As impressive as the new 20-12 is, MPI made it even more appealing by launching its new ‘Try Before You Buy’ program. MPI believes in the power of the Automated Sticky Wax Assembly machine so much that this program allows customers to experience the benefits of the machine first-hand using their own parts. Simply send MPI a sample of your parts for testing to get started. MPI can test with your runners or weld parts to MPI runners. Subsequently, MPI will ship a machine directly to your site, at your cost for a 45-day ‘try before you buy’ trial before you even place an order. “The announcement of this program and the chance to actually experience the results you can achieve before purchasing a machine generated a ton of enthusiasm,” said Aaron Phipps, President of MPI.

Interest was also high for another MPI innovation, the MPI 5X Crossover Injector. The 5X has all the performance capabilities of MPI injectors including Smart Controls but is the first one capable of injecting pattern wax, runner wax, soluble wax, and ceramic materials; all equally well. It allows for rapid and easy changeover from one material tank to another in only 15 minutes utilizing a hot swappable reservoir system that allows for off-machine melting, preparing, and conditioning of materials.

Many visitors also became acquainted with MPI’s Pattern Production services. The MPI Technology Center at MPI’s New York headquarters operates a full range of semi-automatic injectors as well as a fully automated pattern production facility. MPI is the ideal solution for foundries that are at full capacity, or just want to produce higher quality patterns without investing in new equipment. MPI can cost-effectively produce patterns and/or complete trees which can be shipped directly to its customers at a highly competitive price. This can immediately take the stress out of your wax-room operations and help you efficiently and effectively meet your production demands.

During the conference, MPI made available to customers a large library of videos that allowed booth visitors to learn more about MPI’s products and services in visual form. This included MPI’s popular refurbishment program where many before and after pictures of machines that were remanufactured to modern specifications and capabilities caught the eye of customers with vintage machines. Multiple refurbishment customers stopped by the MPI booth to express how happy they were with their machines.

Customers were also pleased to learn that MPI currently has stock wax injectors available for immediate delivery. By eliminating the lead time necessary to build a new machine, your ability to get a new machine on your floor and producing high-quality parts is greatly expedited.

MPI is proud to announce the expansion of their field service team in Europe. The additional support will allow MPI to streamline their service appointment availability and continue to provide stellar customer care support for those who are in need.

MPI extends its gratitude to the Investment Casting Institute for putting on an amazing conference. The show was so successful that it will likely be duplicated in Europe at this year’s European Investment Caster’s Federation (EICF) Show in May. MPI would also like to thank all those who stopped by to learn more about MPI products and services.