Getting Started

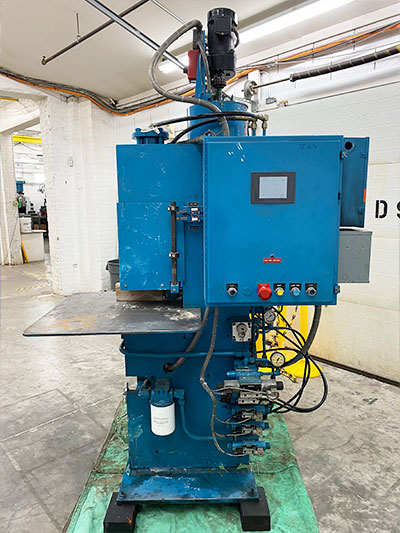

Getting started is easy. Send us a picture of your machine along with the serial number, and we will perform a preliminary review. We can give you a general idea of what will be required to remanufacture your equipment back to its original specifications. We can do this because we built the machine; we know its history and can gauge its current status. Nobody else can do that. Remanufacturing these older machines is very cost-effective, and inoperable machines can immediately start generating revenue again.

The Process

We can handle all the logistics for the transportation of your machine, or you can ship it directly to MPI yourself. We remanufacture machines at our location because of the rigorous quality check points and MPI teams that are involved with the rebuild process. Once MPI receives your machine, we will perform a comprehensive top-to-bottom evaluation and report what the machine needs and what it will cost. Once remanufacturing is complete, we will test your machine to ensure that it meets all OEM specifications. In some instances, we may also recommend upgrades or enhancements to your equipment, which will allow it to perform beyond its original specifications.

Trust no Other

Don’t trust your remanufacturing needs to anyone but the original manufacturer. MPI knows your machine inside and out and understands what it will take to get it back to its original form.

These testimonials say it all:

Ongoing Support

Once your machine is back and generating revenue, we have a global service staff in place to take care of any needs that may arise. Standard or custom service agreements are also available to help ensure that your equipment will operate at optimum levels for another 20+ years.

MPI is currently allocating more space for its New York headquarters to accommodate the high demand for remanufactured equipment. We are also expanding our internal technical support team to streamline turnaround times. A loaner program is under development to assist customers who wish to minimize downtime while their equipment is being remanufactured.

One-Stop Shop

The bottom line… MPI listens to its customers and is always developing new ways to provide value. The MPI Remanufacturing program is an example of why MPI is your one-stop shop. Whether you need to fully automate your wax room injection and assembly or need to have a 30-year-old press remanufactured, we’ve got you covered. When you purchase from MPI, you can count on us to be there to support you.

Just when you think there is no hope for that worn-down workhorse of an MPI Injector, just give us a call, and we will remanufacture your MPI press and show you the way to extended profitability. We even remanufacture other machine brand such as Tempcraft and Jahnke. MPI remanufacturing consultants are ready to discuss your needs. Please contact the MPI Sales Department today to see how we can be of service to you.

Contact us now regarding MPI Certified Remanufacturing