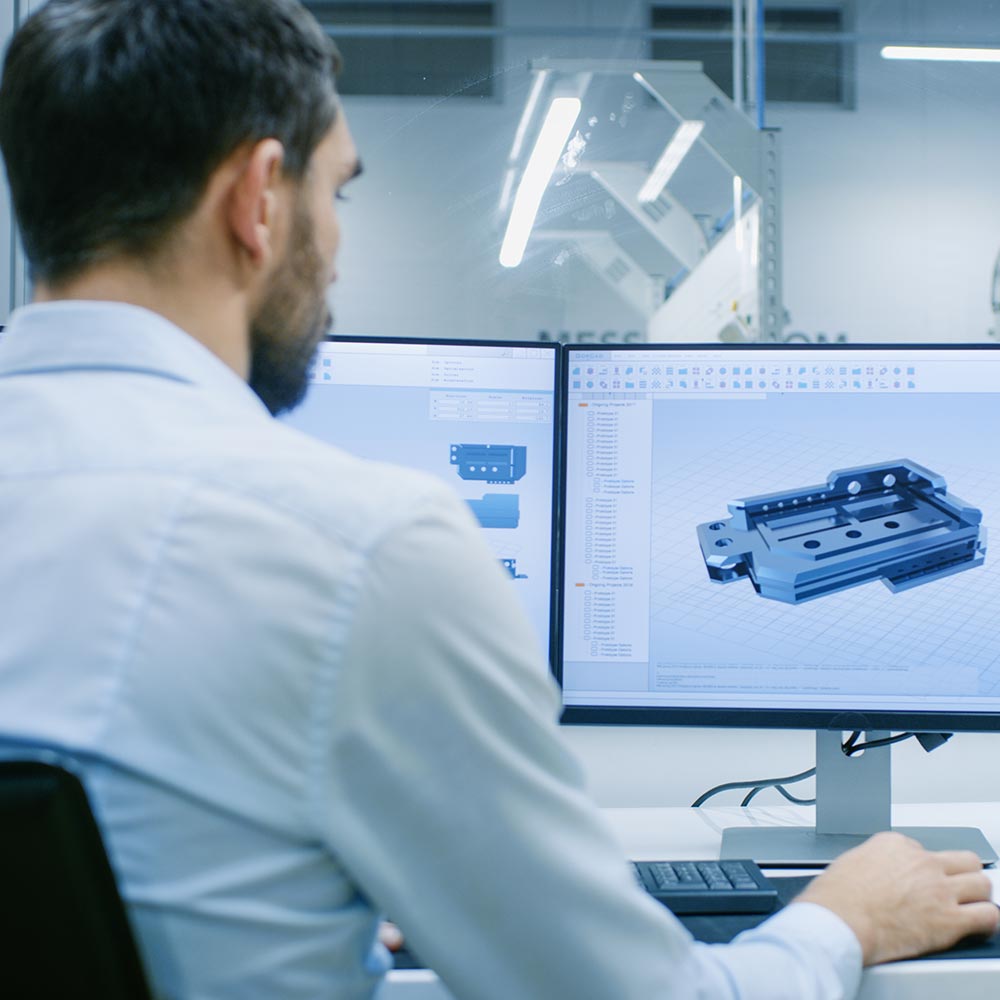

If you’re looking for a career with a dynamic organization where hard work and talent is recognized and appreciated… you’re in the right place. At MPI, we are the Internationally recognized leader in its field. We serve the most advanced aerospace, medical, automotive and even defense contractors on the globe with precision equipment. Learn the skills that will propel your career to new heights for years to come. We’re hiring key Engineering and Support positions throughout the company, and we want to meet you!

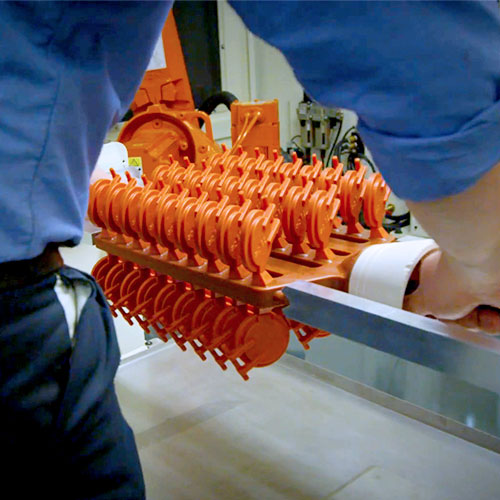

MPI is headquartered in Poughkeepsie, NY, and is proud to be able to stamp all their equipment with the “Proudly Made in America” moniker. Within its facility, there exists a fully functioning Technology Center, showroom, and production facility to demonstrate our state-of-the-art wax room equipment.