MPI 20-20 Dramatically Improves Process Control on Existing Equipment

MPI 20-20 Dramatically Improves Process Control on Existing Equipment

Portable Graphing Technology Works on Other Manufacturers Equipment

Poughkeepsie, NY – February 11, 2011

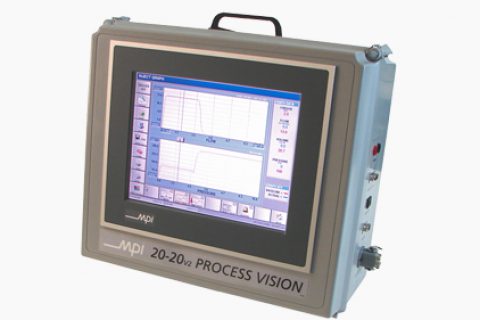

MPI Inc. the worldwide leader in wax-room equipment is seeing dramatic interest in their 20-20 Process Vision Graphing System. The MPI 20-20 is capable of substantially improving the process control of an existing wax injector from another manufacturer.

The 20-20 is a portable device that utilizes MPI’s highly touted “Smart Controls™” technology to monitor the injection process. The 20-20 provides the operator with the ability to graphically monitor every aspect of the injection process including wax flow, wax pressure and wax temperature. This data allows you to understand the differences from machine to machine and correct them.

The MPI 20-20 quickly connects to your injection nozzle where it senses the wax temperature as it enters the wax die. It also has a quick connect to the hydraulic injection cylinder where it senses wax flow and wax pressure. It is from those connections that the injection graphs are created.

The concept can be described very simply. You just inject a good quality pattern on a machine and save it as a baseline graph using the MPI 20-20. You then inject the same wax die on a second machine. After adjusting the controls on the second machine to match those on the first, both machines will produce equal quality patterns. This also eliminates the possibility of having a wax die that will only inject a quality pattern on a specific machine.

|

|

| Injection Graph – Without MPI 20-20 | Injection Graph – With MPI 20-20 |

The MPI 20-20 is equipped with a 12-inch color monitor that features touch screen technology. It comes supplied with easy-to-use menus in five different languages and enough internal data space to store 4,000 injections. The MPI 20-20 also comes network ready.

“By improving process control, even in another manufacturer’s machine, you will now be able to produce repeatable wax patterns, improve pattern quality and improve casting yields – with less wax patterns injected,” said Bruce Phipps, President of MPI. “This technology can have an immediate impact on an underperforming machine.”

About MPI:

MPI has been is the worldwide leader in wax-room equipment for over 38 years, having produced over 1,600 wax injection machines with 98.5% still in active service. As the acknowledged leader in wax-room innovations, MPI has developed and introduced more systems and products than all their competition combined. To learn more, contact MPI directly or visit www.mpi-systems.com