Engineering Custom Solutions at the Heart of MPI

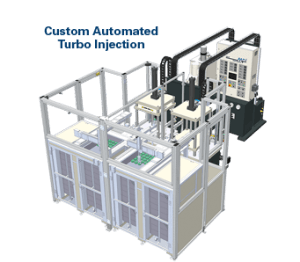

POUGHKEEPSIE, NY – MPI has long been known as the premier manufacturer of wax and ceramic injectors in the world. Now, with over a decade of experience successfully integrating robotics into the wax room, MPI is known equally as the leader in automation.

What’s not as well-known is that MPI, at its heart, is and will always be an engineered solutions company. While MPI’s wax-injector and ceramic-core equipment solutions are highly impressive, the ability to engineer custom solutions to address specific customer problems is what sets MPI apart. MPI’s solutions range from customizing a standard injector with unique features and capabilities to developing an entirely new machine to meet the customer’s unique requirements.

“Machine design challenges are only impossible until someone does it.”Bruce Phipps

President, MPI Inc.

Dual Injector Systems

Several customers demonstrated a need for not just two wax reservoirs on a single injection machine, but two entirely separate injection systems on one machine. MPI engineered an innovative solution to this challenge that not only thrilled this customer but has resulted in requests for quotes for this solution from two more customers.

Total Redesign of Range of Large Clamp Force Presses

While MPI has long built an excellent line of large (greater than 100 ton clamp force) four-post machines, it is never satisfied with past successes. The newly redesigned 2015 model is less expensive than previous models, has more capabilities and a smaller footprint, and is easier to maintain. The new model is a hit, and demand has been high. Just as importantly, each customer’s machine can be adapted to meet the customer’s unique requirements without having to reengineer the machine each time.

Not to be outdone by the team redesigning the large presses, MPI’s new product development team is creating a new design approach for its popular Model 55 series. The new line will provide better pricing for base model machines, more flexible options than ever before, and a wide range of function and feature choices while providing the same industry-leading quality for which MPI is known.

Challenges to Automation

Many of the problems associated with automating processes in the wax room, including runner variation, tool variation and part variation, are being solved by the MPI Automation Team. Quick and effective methods have been implemented that will allow the machine to automatically measure defects or variations in wax components and then compensate for them. These methods have been tested and advanced to the point where MPI anticipates being able to introduce them to the market within the next few months. This development will allow wax-room automation to make a quantum leap forward and will make cost-effective automation available to commercial foundries.

Soluble Wax Melting and Conditioning

As valuable as using soluble wax is in the investment-casting industry, it also presents some of the trickiest problems investment casters face. Soluble wax is notoriously hard to melt and condition, and its injection properties are usually very different from pattern wax. As a result, many foundries try to do as little injecting of soluble cores as necessary and usually devote their oldest and worst-performing injectors to the task. In response to many requests to help solve this problem, MPI is undertaking a project to address soluble wax melting, conditioning, and injecting and will be introducing new products dedicated to this unique challenge. This will provide customers who must use soluble cores with the same quality and process control as they would for any other wax-injection projects.

While MPI has built its reputation on manufacturing quality equipment, it has never lost its skill and desire to tackle complex problems and produce well-thought and designed engineered solutions.

About MPI:

MPI is the worldwide leader and innovator in wax-room equipment, featuring a broad range of wax-injection machines that generate higher casting yields with increased productivity and throughput. As the acknowledged leader in wax-room innovations, MPI has developed and introduced more systems and products than all of its competition combined. In addition to producing industry-leading wax-injection systems, MPI offers total wax-room automation, from wax injection to wax assembly, using integrated robotics technology. Automation also allows MPI to provide cost-effective pattern and assembly services that can be shipped directly to its customers. All MPI equipment is backed by a world-class customer service team featuring a Global Support Services program.